The choice of insulation tape is critical in transformer design and maintenance, influencing both performance and safety. Among the various options available, electrical filament tape and glass cloth tape stand out as two prominent choices. This article explores the key differences between these types of insulation tapes and their specific applications in oil-filled transformers versus dry-type transformers.

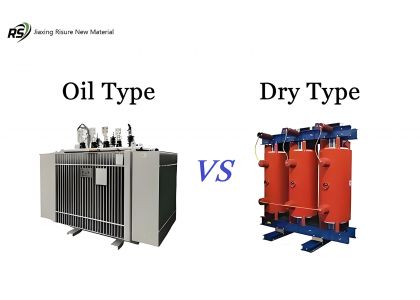

Transformers are essential components in the electrical grid, enabling the transmission and distribution of electricity. There are two primary categories of transformers: oil-filled and dry-type.

Oil-Filled Transformers: These transformers rely on mineral oil as both a coolant and an insulating medium. The oil provides excellent dielectric strength and thermal conductivity, helping to maintain operational efficiency even under heavy loads.

Dry-Type Transformers: Instead of using oil, dry-type transformers utilize air or other materials for cooling and insulation. They typically operate at lower voltages and are favored for indoor environments due to their reduced fire risk and environmental safety.

The choice of insulation tape in these transformers varies significantly due to differing operational conditions, environmental factors, and the materials used in their construction.

Insulation tapes perform several vital functions within transformers. They provide:

· Electrical Insulation: Preventing electrical discharge and maintaining operational safety.

· Mechanical Protection: Shielding components from physical damage and wear.

· Thermal Management: Assisting in heat dissipation to maintain optimal performance.

When selecting insulation tapes for oil-filled and dry-type transformers, it is crucial to consider their operating conditions and the unique properties of the tapes available.

Electrical filament tape is crafted from a base of polyester film with a strong adhesive layer. This tape is widely recognized for its versatility and effectiveness in high-voltage applications.

Key Characteristics:

· High Dielectric Strength: With excellent electrical insulation properties, electrical filament tape is ideal for preventing electrical leakage.

· Temperature Resistance: Capable of withstanding temperatures up to 130°C (266°F), it is suitable for both oil-filled and dry-type transformers where heat resistance is essential.

· Mechanical Durability: The high tensile strength of this tape allows it to withstand mechanical stresses, making it reliable in demanding applications.

In oil-filled transformers, electrical filament tape is often used to bundle and secure wire harnesses, ensuring the integrity of electrical connections under conditions where the medium may interact with various chemical components of the oil. For dry-type transformers, the tape serves a similar purpose but might also cater to higher temperature environments.

Glass cloth tape is a type of insulation tape made from woven fiberglass material. It excels in applications requiring enhanced mechanical strength and thermal resistance.

Key Characteristics:

· Thermal Stability: Glass cloth tape can typically endure temperatures up to 180°C (356°F), making it particularly suited for dry-type transformers subject to higher operational temperatures.

· Non-Flammability: This type of tape is non-flammable, providing an extra layer of safety, which is crucial in environments where fire risk needs to be minimized.

· Insulating Properties: The fiberglass material inherently offers high dielectric strength, preventing electrical failures and ensuring system reliability.

In oil-filled transformers, glass cloth electrical tape is effective in applications demanding high thermal resistance and mechanical durability. It is particularly useful in insulating components exposed to higher temperatures or external physical stress.

When comparing electrical filament tape and glass cloth tape, several factors must be considered:

Temperature Tolerance:

Electrical filament tape withstands up to 155°C, making it highly effective in moderate thermal environments. In contrast, glass cloth tape can handle temperatures as high as 180°C, making it suitable for applications with more extreme temperature conditions.

Mechanical Properties:

Electrical filament tape is designed for good mechanical strength, suitable for bundling and securing, while glass cloth tape provides superior resistance against abrasion and wear, ideal for protection in environments involving physical stress.

Application Versatility:

o While electrical filament tape is versatile across both types of transformers, glass cloth tape is often preferred in applications where enhanced thermal stability and abrasion resistance are needed, particularly in dry-type transformers.

The selection of insulation tape is crucial for the efficient operation and longevity of both oil-filled and dry-type transformers. While electrical filament tape provides excellent electrical insulation, mechanical strength, and temperature resistance, glass cloth tape offers superior thermal stability and durability in more extreme environments. By understanding the specific needs of each transformer type and the characteristics of the available insulation tapes, engineers and professionals can make informed selections that ensure optimal performance and safety in electrical systems. Utilizing the strengths of electrical filament tape and glass cloth tape can significantly enhance the reliability and efficiency of transformers, underscoring the importance of appropriate insulation materials in modern electrical engineering.