PTFE tape is made by using glass fiber as the base cloth, coating with PTFE emulsion and drying it to form PTFE glass fiber cloth. Further coated with silicone adhesive to produce a high temperature resistant tape. It is widely used in the fields of packing (including thermoplastic, vacuum bagging), compositing, thermoplastic seal, electronic and electric.

Datasheet

| Item No. | J-710 | J-710 | J-710 | J-710 | J-710 |

| Thickness | 0.13mm | 0.18mm | 0.20mm | 0.25mm | 0.30mm |

| Base Material | PTFE fiberglass cloth | PTFE fiberglass cloth | PTFE fiberglass cloth | PTFE fiberglass cloth | PTFE fiberglass cloth |

| Adhesive | Silicone | Silicone | Silicone | Silicone | Silicone |

| Adhesion to Steel | 22 N/100mm | 28 N/100mm | 35 N/100mm | 48 N/100mm | 62 N/100mm |

| Tensile Strength | 900 N/100mm | 1700 N/100mm | 2300 N/100mm | 2750 N/100mm | 3650 N/100mm |

| Max Width | 1250mm | 1250mm | 1250mm | 1250mm | 1250mm |

| Temperature Resistance | -70~260°C | -70~260°C | -70~260°C | -70~260°C | -70~260°C |

Product Description

PTFE Coated Fiberglass Fabric Tape is engineered from high-quality fiberglass fabric, meticulously impregnated with PTFE (polytetrafluoroethylene) dispersion and subsequently sintered to form a robust and versatile adhesive tape. This innovative product marries the strength and durability of fiberglass fabric with the non-stick and heat-resistant properties of PTFE, making it suitable for a plethora of industrial applications. Its dependable characteristics have established it as a preferred choice in industries such as aerospace, food processing, electronics, insulation, and chemical manufacturing.

Our PTFE glass tape features a single-sided treatment coated with a high-temperature, silicone pressure-sensitive adhesive, ensuring optimal adhesion and release characteristics. Available in log rolls or slitted tapes, it also comes with a yellow textured PVC release liner, allowing for easy application. For convenience, self-wound rolls without a liner are also offered.

Key Features

The PTFE Coated Fiberglass Fabric Tape is designed to deliver superior performance and durability, highlighted by the following key features:

· High Temperature Resistance: Capable of withstanding continuous operating temperatures from -148℉ to 500℉ (-100℃ to 260℃) and can withstand short-term exposure up to 572℉ (300℃).

· Non-Stick Surface: The PTFE coating allows for easy release from adhesives and other sticky substances, making it ideal for various applications.

· Excellent Chemical Resistance: Boasting resitance against strong acids, alkalis, and a variety of organic solvents, the tape is designed for longevity in harsh environments.

· Waterproof and Smooth Surface: Ensures easy cleaning and maintenance, along with enhanced operational efficiency.

· High Insulation Performance: Provides excellent electrical insulation, ensuring safety in high-voltage applications.

· Durability: Made from high-grade fiberglass and premium PTFE resin, it features low friction, high tensile strength, and superior wear resistance.

Application

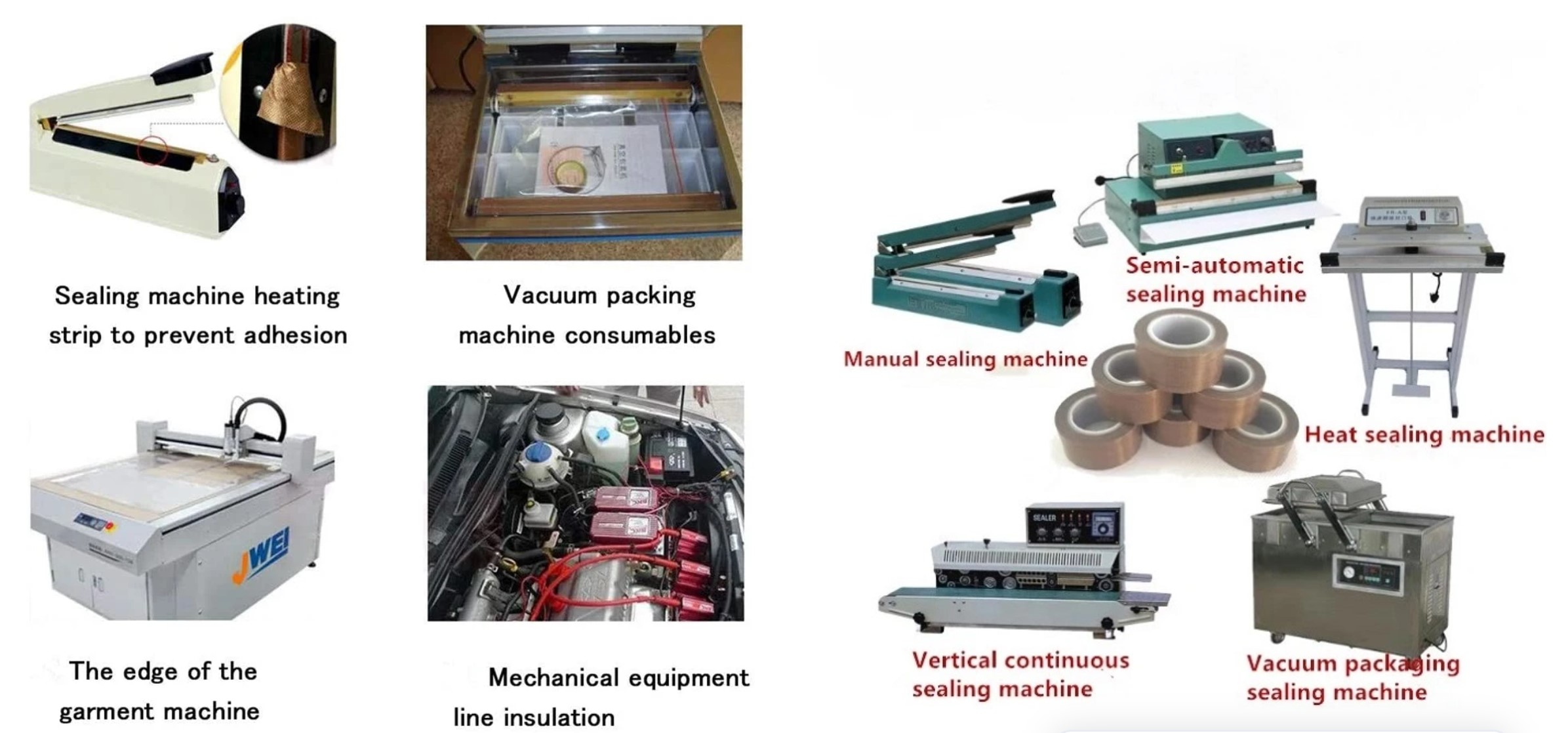

The versatility of PTFE Fabric Tape allows for a wide array of applications across various sectors:

· Aerospace Industry: Used as glass breaker tape, heater cable wraps, and mold releases, ensuring the safe operation of critical components.

· Food and Medical Industries: Acts as a non-stick liner in heat sealers, maintaining hygiene and integrity in food packaging.

· Packaging Sector: Ideal for covering sealing jaws on L-bar sealers and blister packing machines, its non-stick properties facilitate smooth operation.

· Electronics: Used in cable wrapping, splicing, and as insulating material, offering robust electrical resistance and stability.

· Construction and Insulation: Functions as a high-temperature insulation jacket in various construction applications.

· General Manufacturing: Serves as a durable lining for conveyor belts and chutes, providing a slick, non-stick surface to prevent material buildup.

Application

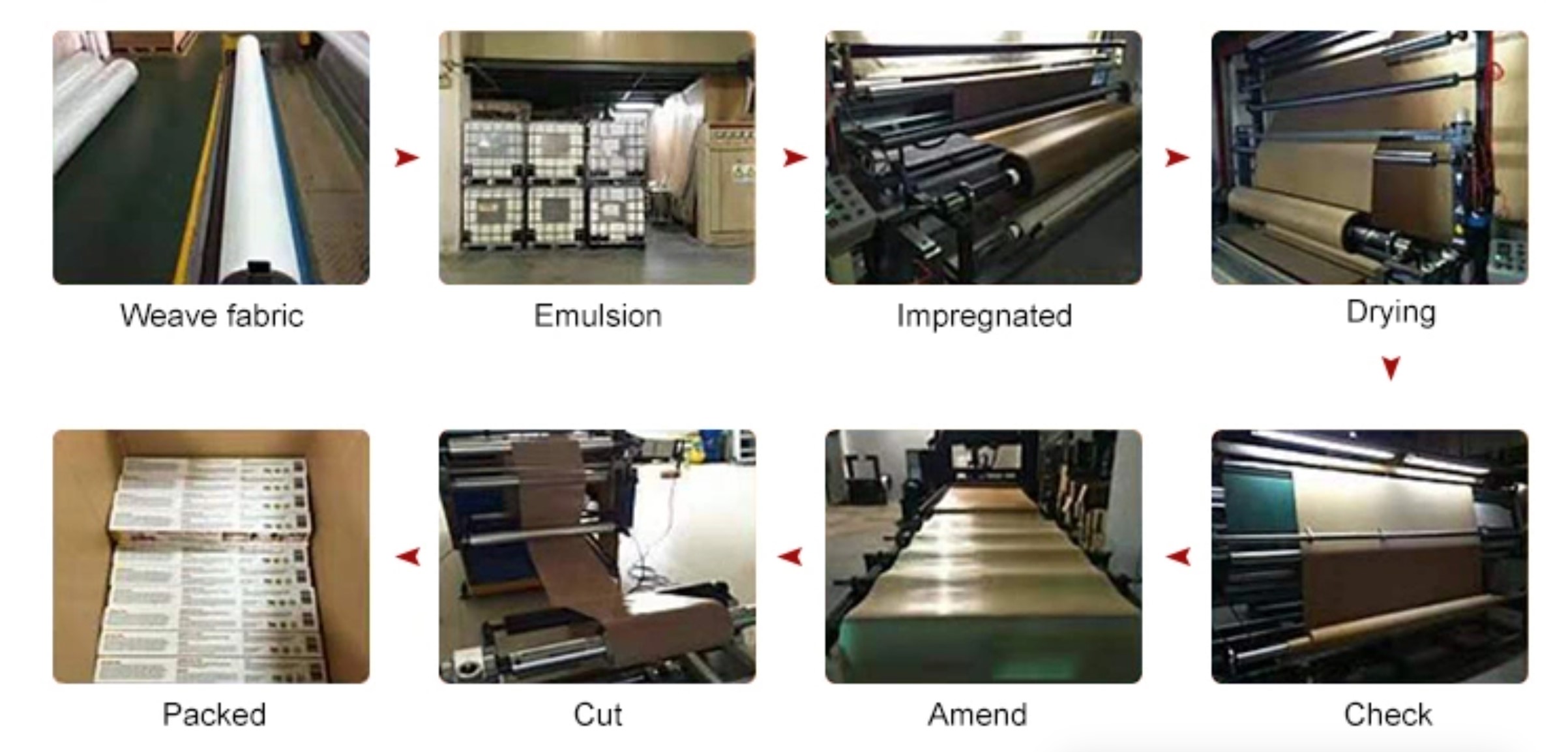

Production Process

Summary

PTFE Fiber Glass Fabric Tape stands out as a high-performance solution for your adhesive needs, offering a combination of heat resistance, chemical stability, and non-stick characteristics. This fabric tape adhesive is versatile enough for applications in industries ranging from aerospace to food processing, making it a crucial component for modern manufacturing processes. With its robust design and multiple advantages, this tape is ideal for those requiring reliable heat resistant adhesive tape that outperforms standard options.

Whether you're looking to enhance packaging efficiency, improve safety standards in food production, or utilize effective insulation in construction projects, PTFE Coated Fiberglass Fabric Tape delivers unmatched performance. Explore the possibilities with this exceptional product and experience the advancements it brings to your operations today.

A:PTFE-glass tapes are heat-resistant and often meet UL Class 150 (250 °C) ratings. For example, a standard PTFE glass tape is UL510A certified and handles high-heat environments. The glass-fabric reinforcement gives it excellent dimensional stability (it won’t shrink) and mechanical robustness. Electrically, it is a good insulator (the glass cloth provides dielectric strength, while the PTFE coating adds arc resistance).

A:We provide PTFE glass cloth tape in widths from a few mm up to several hundred mm and lengths per roll as needed. MOQ can be small; sample rolls are available. Because of its specialty nature, lead times are around 2–4 weeks. We ship worldwide; our factory packs the tapes securely, and uses air or sea freight as required. Proximity to major Chinese ports (Shanghai) means fast export shipments for international orders.

A: Yes, we are pleased to offer free samples for your evaluation. Please contact us with your requirements, and we will arrange the shipment promptly.