Wire harness tape is characterized by excellent wear resistance and noise reduction performance, it is often used for shock absorbing noise reduction, wire harness tying and cable fixing.

Wire harness tape is widely used in aircraft, ships, rail locomotives and electrical appliances to meet the needs of different harness bundling and shock absorption and noise reduction.

Product Introduction

In the automotive and industrial sectors, the integrity of electrical connections is paramount. A critical component in maintaining these connections is the “PET cloth wire harness tape”—a specialized tape designed for wrapping, insulating, and protecting wire harnesses. This tape, often referred to as” fabric non-adhesive wire loom wrap” or “adhesive-free wire loom wrap”, combines durability, flexibility, and superior adhesion, making it an essential tool for various applications. In this article, we will explore the characteristics, benefits, and applications of “wire harness tape”, emphasizing its role in ensuring reliable electrical performance.

Datasheet

| Item No. | W514 | W525 | |

| Thickness | 0.14mm | 0.22mm | |

| Base Material | Polyester Fabrics | Polyester Fabrics | |

| Adhesive | Synthetic Rubber | Acrylic | |

| Abrasion Resistance | A | D | |

| Sound Damping | / | / | |

| Tensile Strength | ≥ 60 N/10mm | ≥ 155 N/10mm | |

| Elongation at Break | ≥ 10% | ≥ 15% | |

| Adhesion to Steel | ≥ 2.5 N/10mm | ≥ 2.5 N/10mm | |

| Adhesion to Backing | ≥ 2.0 N/10mm | ≥ 2.5 N/10mm | |

| Temperature Range | -40~125°C | -40~150°C | |

|

Tearable by Hand |

Y | N | |

Key Features of PET Cloth Wire Harness Tape

Material Composition

PET cloth wire harness tape is primarily made from polyethylene terephthalate (PET) fabric, offering remarkable resistance to abrasion and environmental factors. The tape’s high-quality woven material provides flexibility, allowing it to conform to the shapes of wires and harnesses. Additionally, the robust adhesive on one side ensures a strong bond with the wire harness or cable, securing it in place effectively.

Adhesive Quality

The adhesive used in wiring loom tape is specifically designed for automotive and industrial applications. It is pressure-sensitive, allowing for easy application and strong adhesion to various surfaces. This feature is particularly beneficial in situations where

wire protection is needed against vibration, temperature fluctuations, and mechanical stress.

Abrasion and Wear Resistance

One of the defining characteristics of PET cloth wire harness tape is its "abrasion resistance". This quality protects wires from damage due to rubbing against other components or surfaces, which is essential for maintaining the longevity of electrical systems. With a superior tensile strength of more than 20N/cm, this tape can withstand demanding conditions while ensuring the protection of wire harnesses.

Noise Dampening

The cloth material used in the tape also serves a noise-dampening function. By reducing vibrations and minimizing noise, it is an ideal solution for applications where sound attenuation is critical, such as in automotive interiors or electronic devices.

Temperature Resistance

PET cloth wire harness tape can perform reliably in extreme temperature ranges, making it suitable for various applications, from automotive under-the-hood wiring to industrial machinery. Its operational capabilities extend from -40℉ to 257℉, ensuring that it maintains its integrity and protective qualities under harsh conditions.

Easy Application and Handling

A key advantage of this tape is its ease of use. The "adhesive-free wire loom wrap" can be torn by hand, eliminating the need for scissors and facilitating quick and convenient installation. This feature is crucial in dynamic work environments where time efficiency is necessary.

Applications of PET Cloth Wire Harness Tape

1. Automotive Industry

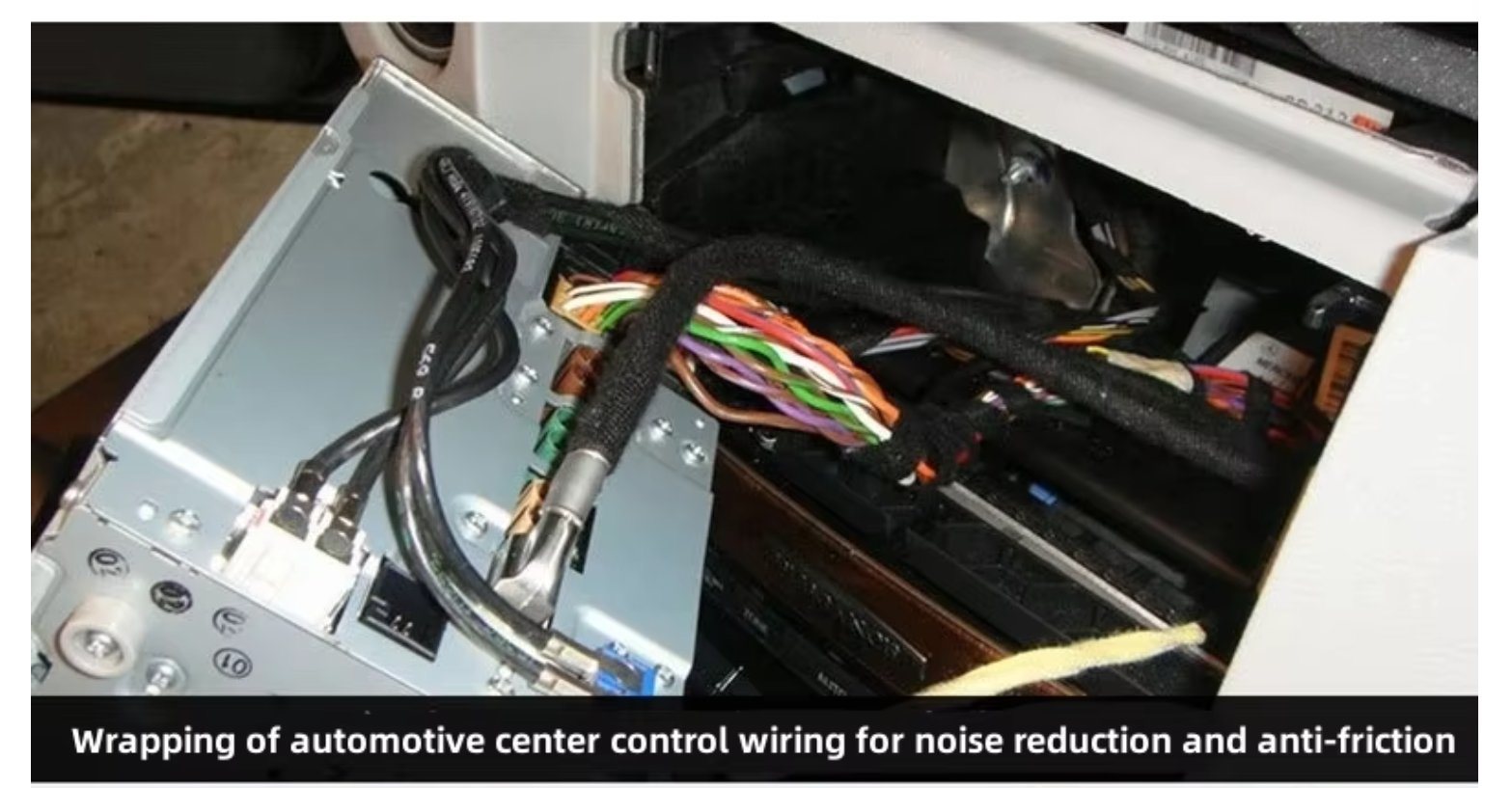

In the automotive sector, wiring harness tape is widely used to secure and protect electrical wiring in vehicles. It not only shields the wiring from moisture, heat, and environmental damage but also enhances the overall aesthetics by providing a clean, professional look. This tape can handle the rigors of automotive applications, ensuring that vital connections remain intact throughout the vehicle's lifespan.

2. Aerospace Industry

PET cloth wire harness tape is also invaluable in the aerospace industry, where it is employed to secure wiring in airplanes and spacecraft. The harsh flight conditions necessitate reliable insulation and protection, making this tape an ideal choice due to its heat resistance and durability.

3. Electronics Industry

In electronics, wire harness tape protects and secures wiring in devices such as computers and televisions. Its insulating properties and mechanical strength reduce the risk of electrical failures associated with wear and tear.

4. Marine Applications

The marine industry benefits from PET cloth wire harness tape that protects electrical wiring from harsh saltwater environments. This tape ensures that connections remain functional even in the face of moisture and other corrosive elements.

5. Industrial Applications

In various industrial settings, wiring harness tape is employed to secure electrical wiring in machinery and equipment. Its abrasion resistance, temperature stability, and mechanical strength make it suitable for industrial environments, ensuring that wires are protected from damage due to mechanical stress and exposure to chemicals.

Advantages of Using PET Cloth Wire Harness Tape

Durability and Longevity

The use of high-quality materials in PET cloth wire harness tape results in an extremely durable product, capable of withstanding wear and tear over extended periods. Its effective performance in demanding environments contributes to the longevity of both the tape and the wiring it protects.

Versatility

Due to its multiple applications across industries, PET cloth wire harness tape is a versatile solution for wire protection, insulation, and management. Whether used in automotive, aerospace, marine, or industrial applications, its characteristics meet the diverse needs of professionals.

Environmental Resistance

This tape performs exceptionally well against environmental challenges, such as temperature extremes and chemical exposure. Its flame-retardant properties further enhance safety, making it reliable in high-risk.